We are specialised in solutions in the area of electrical power transmission, especially in mechanical aspects and long-term reliability. As a spin-off of the Swiss Federal Laboratories for Materials Science and Technology (Empa) and ETH Zürich, we have experience in the modelling and calculation of damage mechanisms of the relevant materials and continue to foster cooperation with the scientific community.

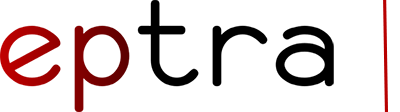

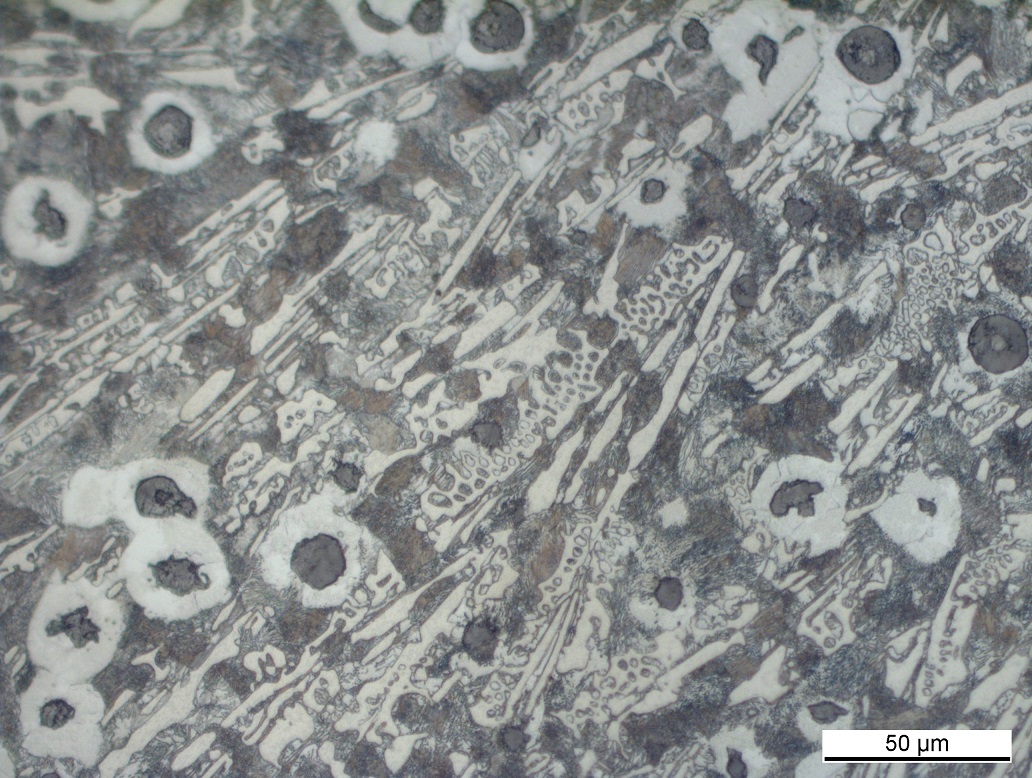

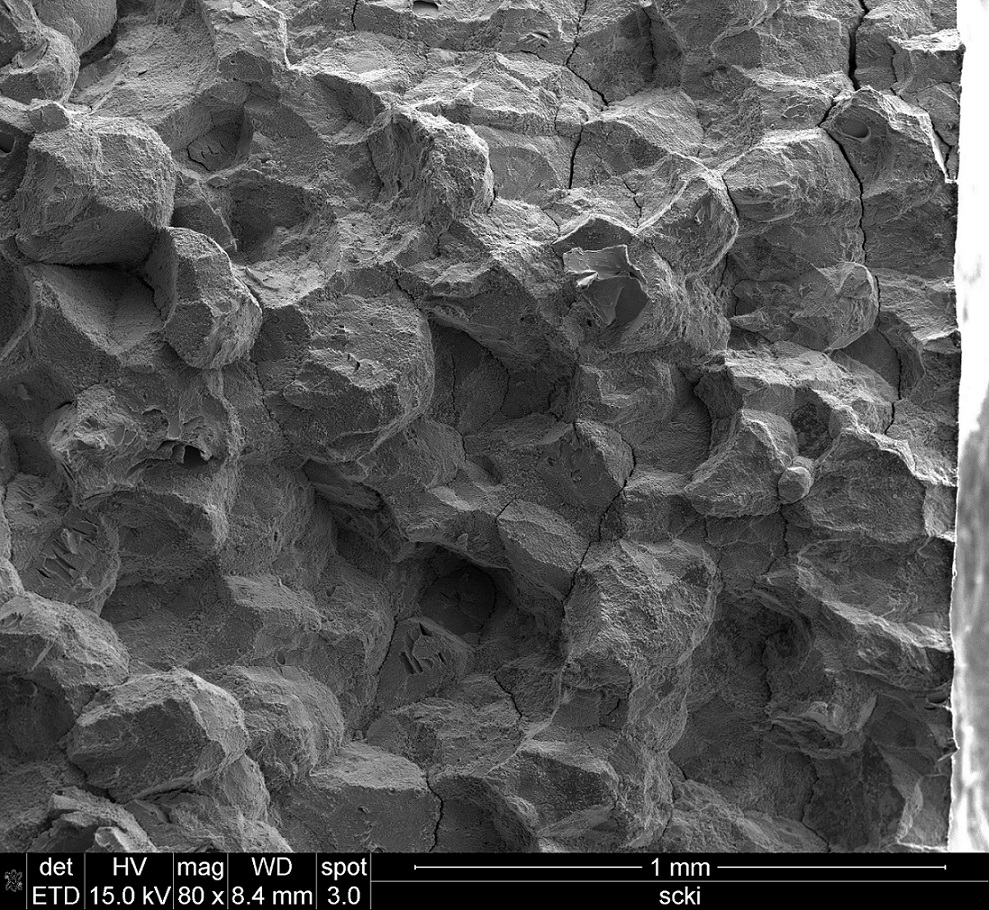

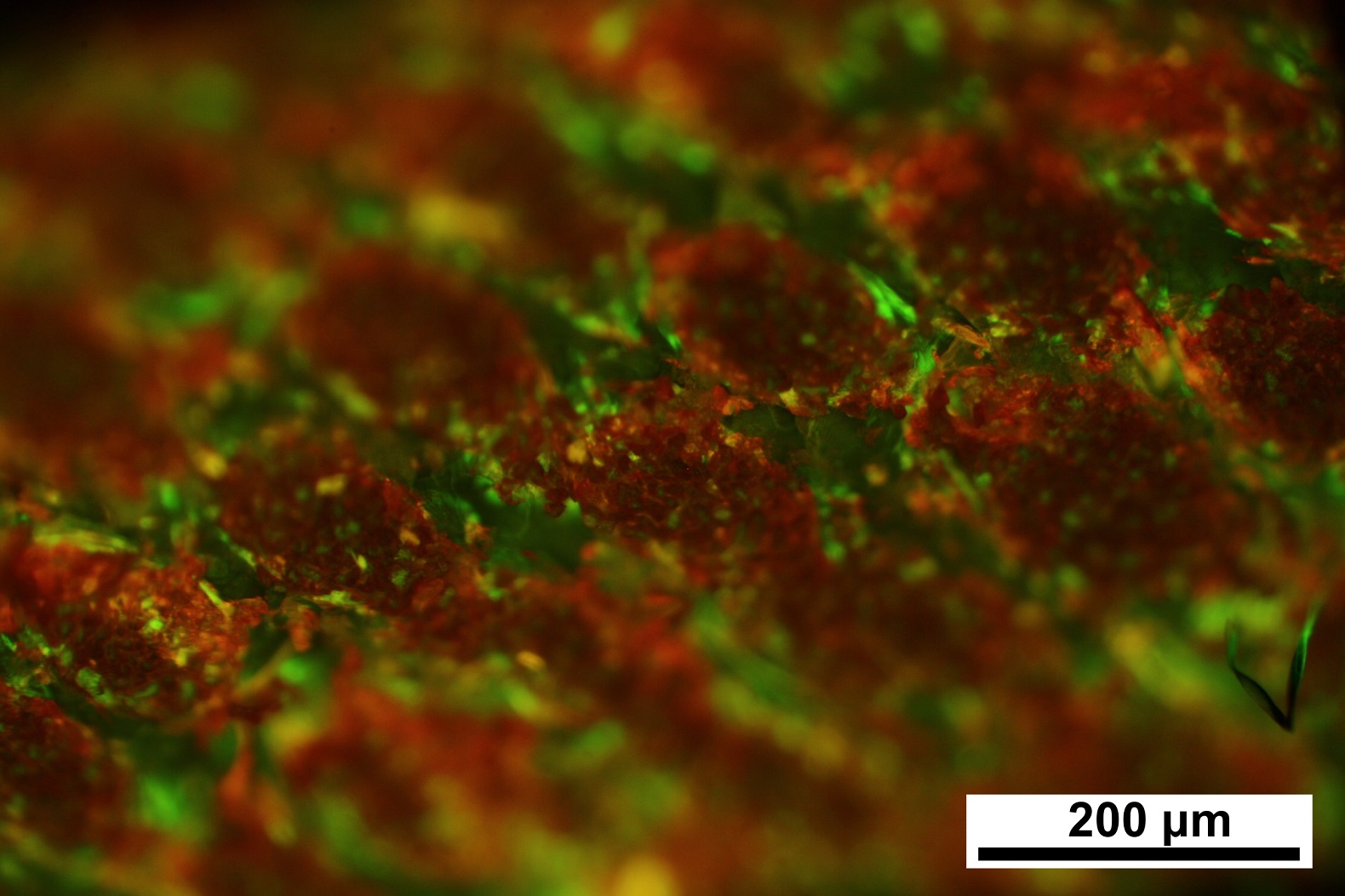

In damage cases, it is essential to determine the root cause in a failure analysis in order to avoid recurring damage. With a combination of damage/fracture pattern analysis, material analysis (mechanical properties, metallography, composition), simulations, and reproduction of the damage in laboratory tests, the cause of damage usually can be determined unambiguously. Our expertise is centred around the particular problems of materials and components for electrical power transmission.

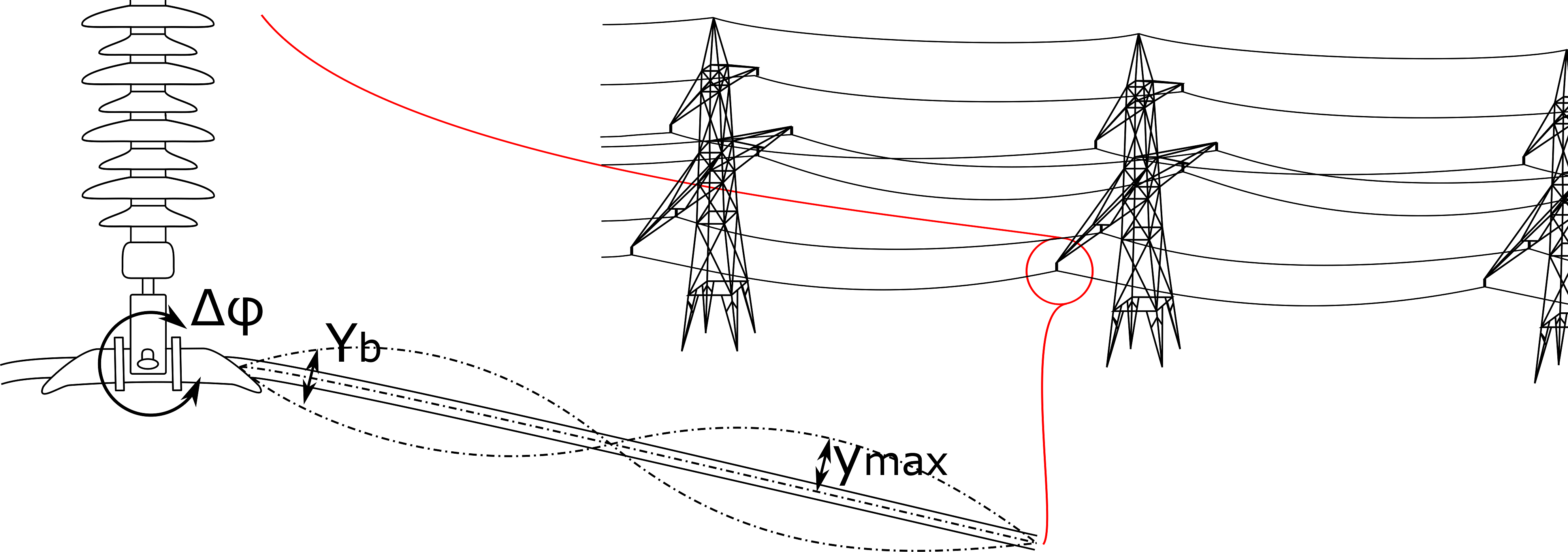

Major parts of the grid are more than 50 years old. The materials, designs, and processes used in the past differ considerably from the current state of technology, so that the application of today's design methods and fittings can lead to damage. With our analytical techniques we help to develop and review procedures for condition assessment and preventive maintenance in the asset management.

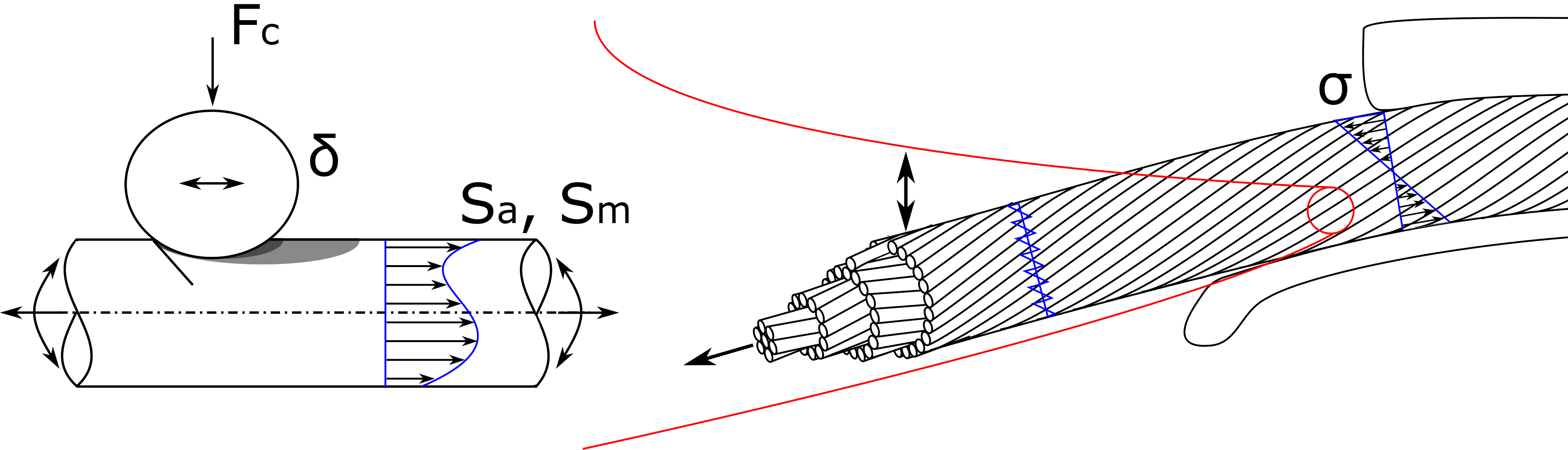

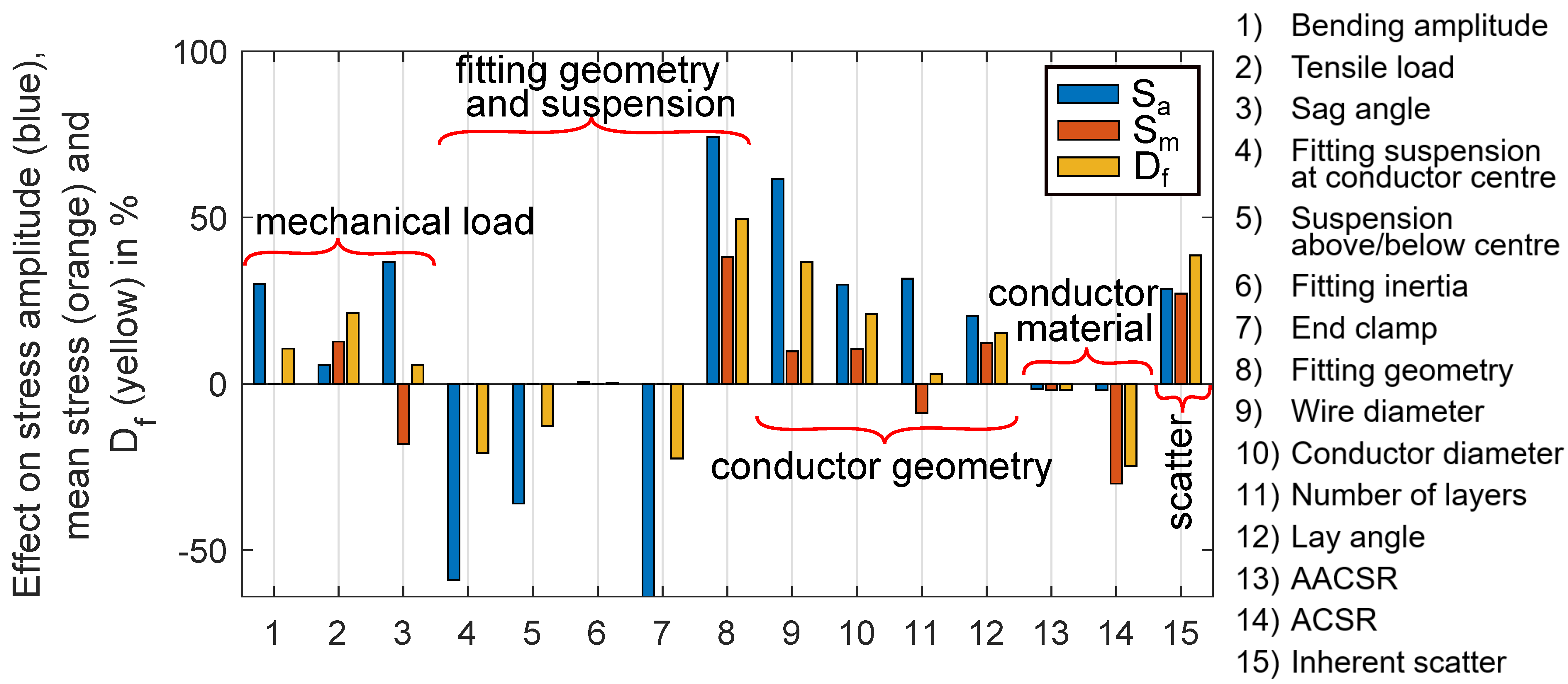

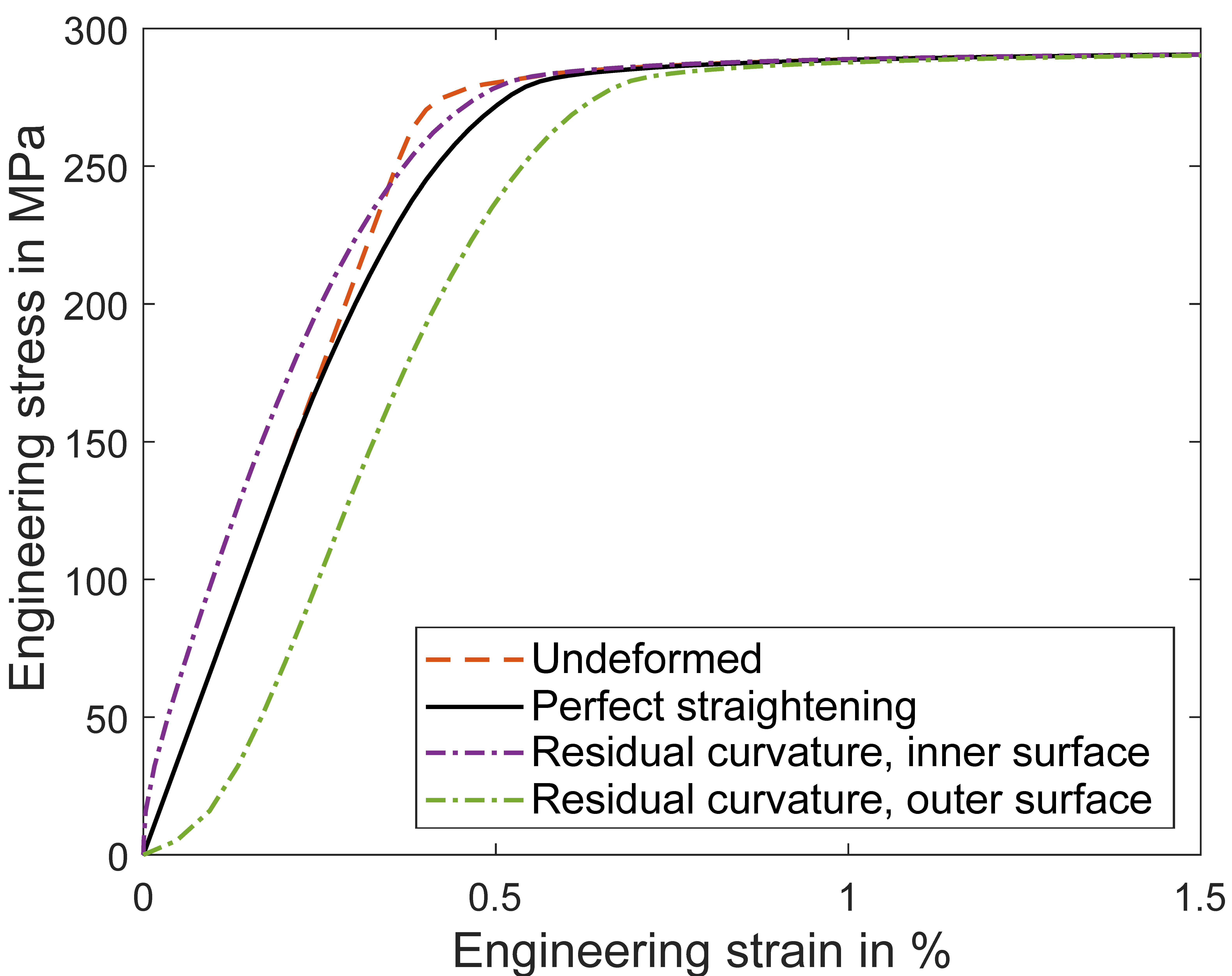

Often the damage mechanisms, such as the progressive loss of strength at temperature, the reduction of the clamping force and increased contact resistance due to creep, and fatigue are very long-term effects. In material and especially in component tests (e.g. type tests), modelling the material behaviour is often unavoidable. We are happy to contribute our experience with accelerated ageing in the laboratory and procedures for fault testing (defect screening) in the laboratory to the testing of your components and fittings.

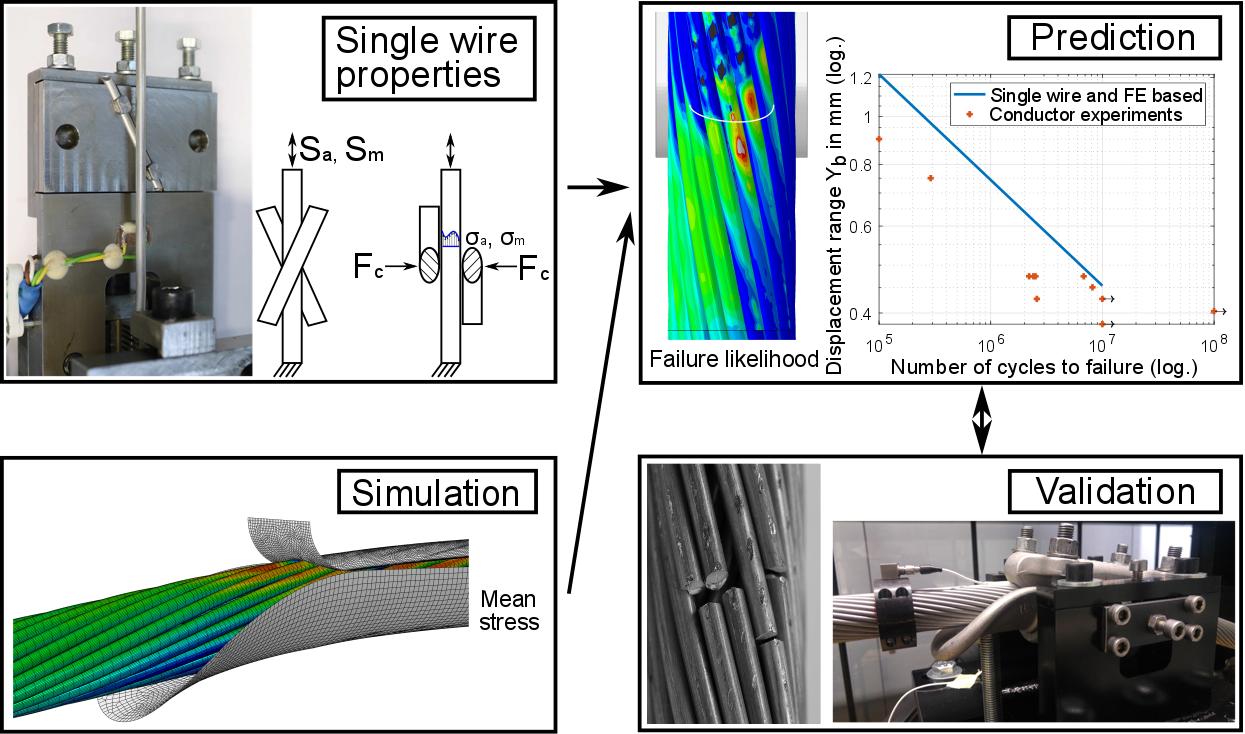

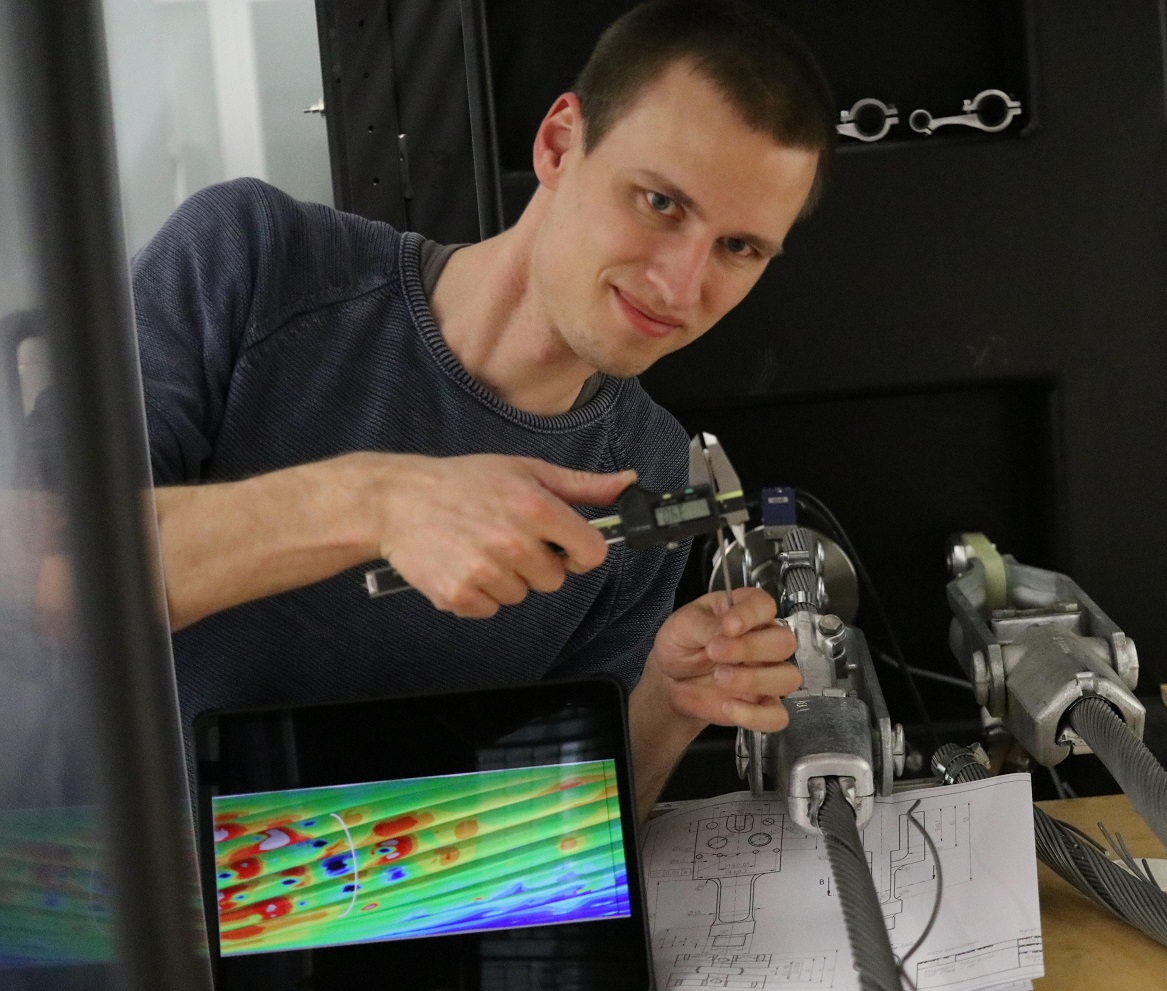

We are equipped for the experimental measurement and the modelling of material parameters as input data for simulations. For example, we are able to test tensile strength and plastic deformation at room and maximum operating temperature, creep and fatigue on single wires as well as whole conductors or components. With our experience in test stand development, especially for component and conductor/cable tests, we also support the rapid and reliable expansion of your own test capacities.

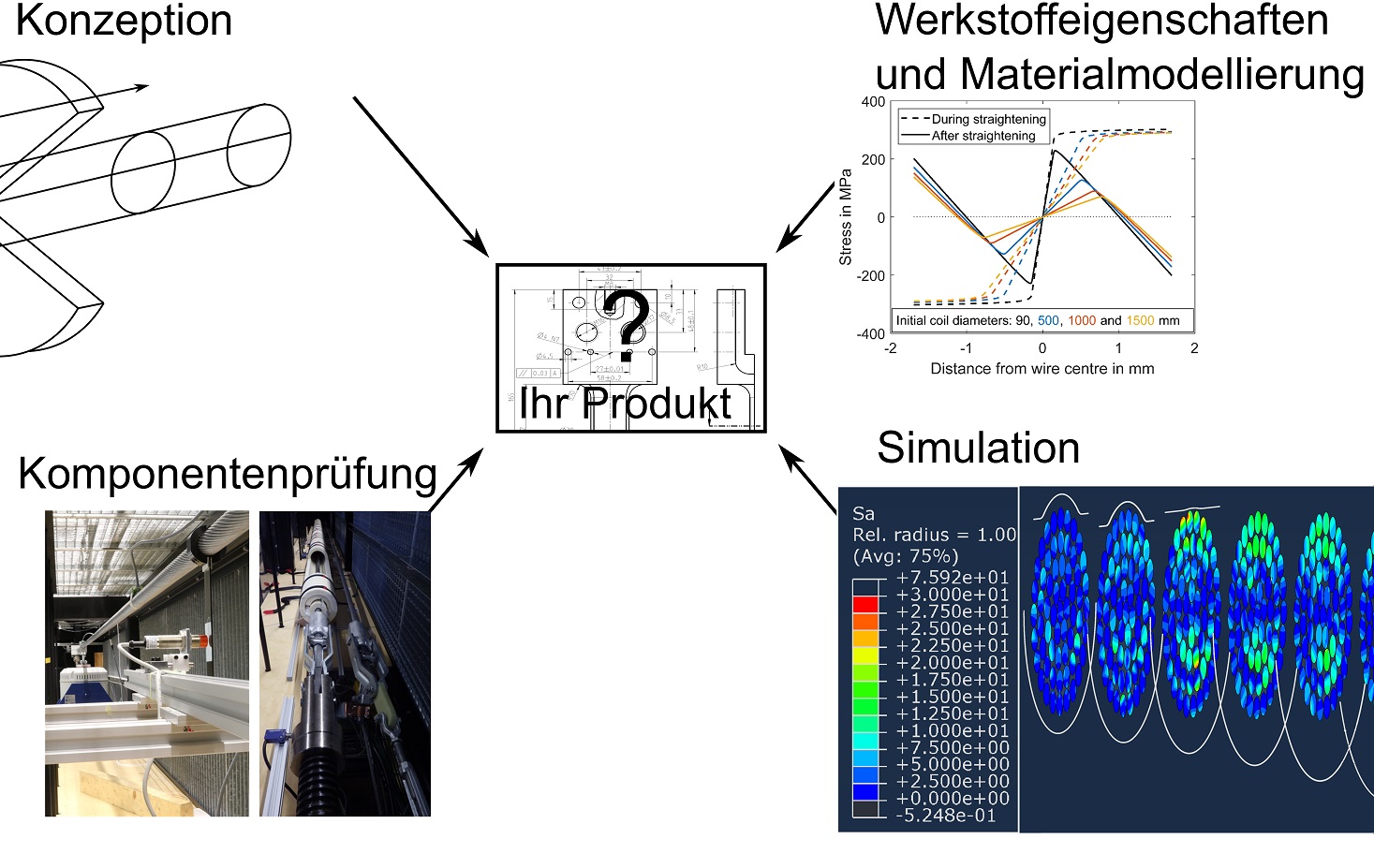

Mechanical and thermal analysis with finite element simulations, modelling and testing are the backbone of our work. With our experience in material modelling, simulation, accelerated ageing and component testing, we are happy to support you in your product development.