The experimental characterisation and modelling of material properties is one of our core competences. Especially for electrical applications, highly non-linear material properties such as temperature-dependent plastic deformation and strength, fretting fatigue, annealing and creep often play an important role.

For simulation, modelling is always an essential part of material testing.

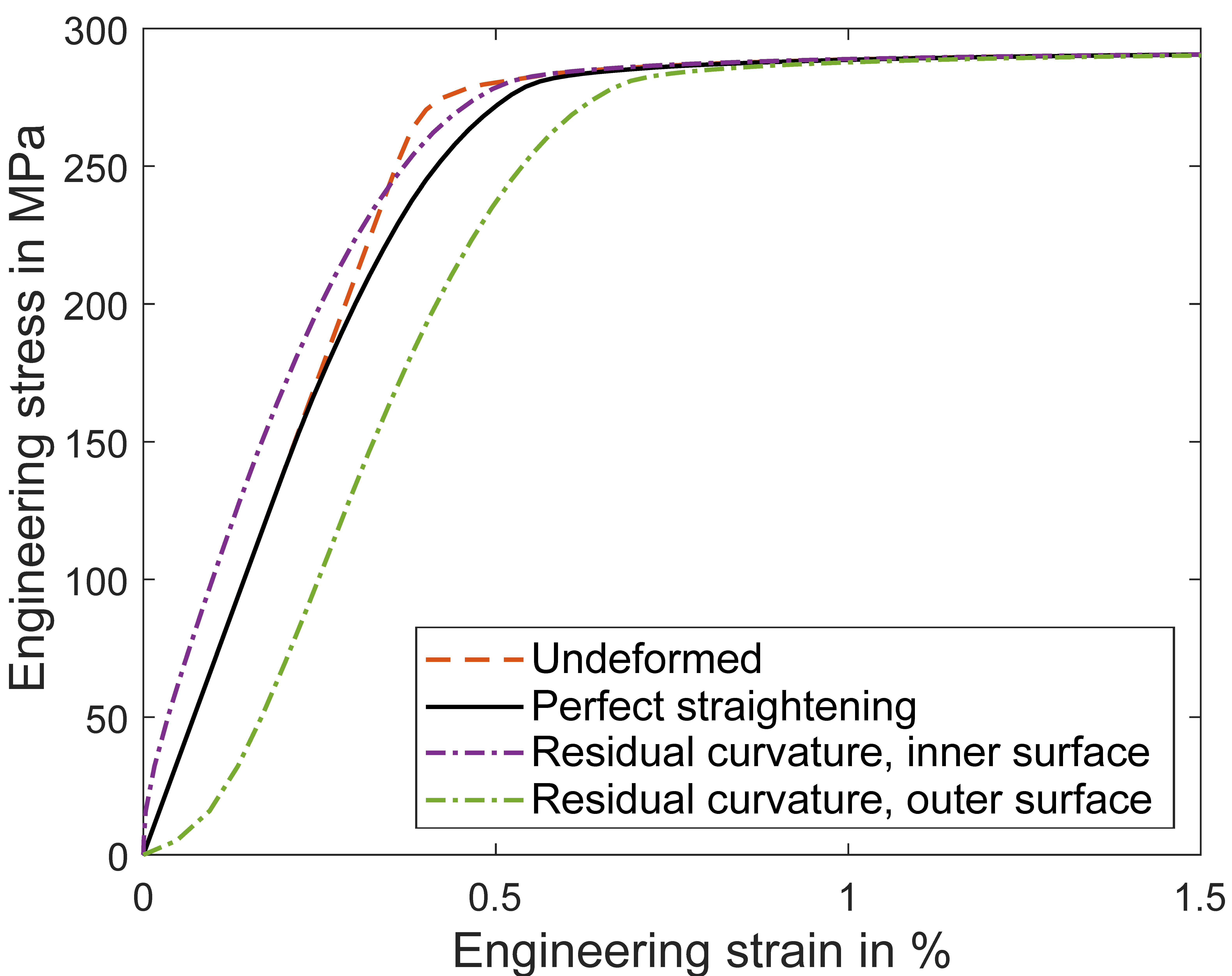

Figure: Effect of residual stresses from straightening of wires on the stress-strain diagram as well as the dependence of the measurement result on the measurement location for insufficiently straightened specimens (simulation).

If no standardised tests are available for your damage mechanisms, we will develop suitable test stands for material and component properties for you. In this way, we also support the rapid and reliable expansion of your own test capacities.

Often the accuracy of simulations is limited by the underlying material properties. The measurement of material properties is essential for reliable results. Material models can reduce the inherent scatter of experimental data and allow interpolation between experimental data.

|

|

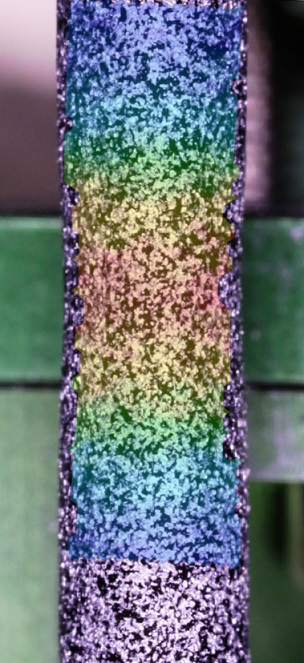

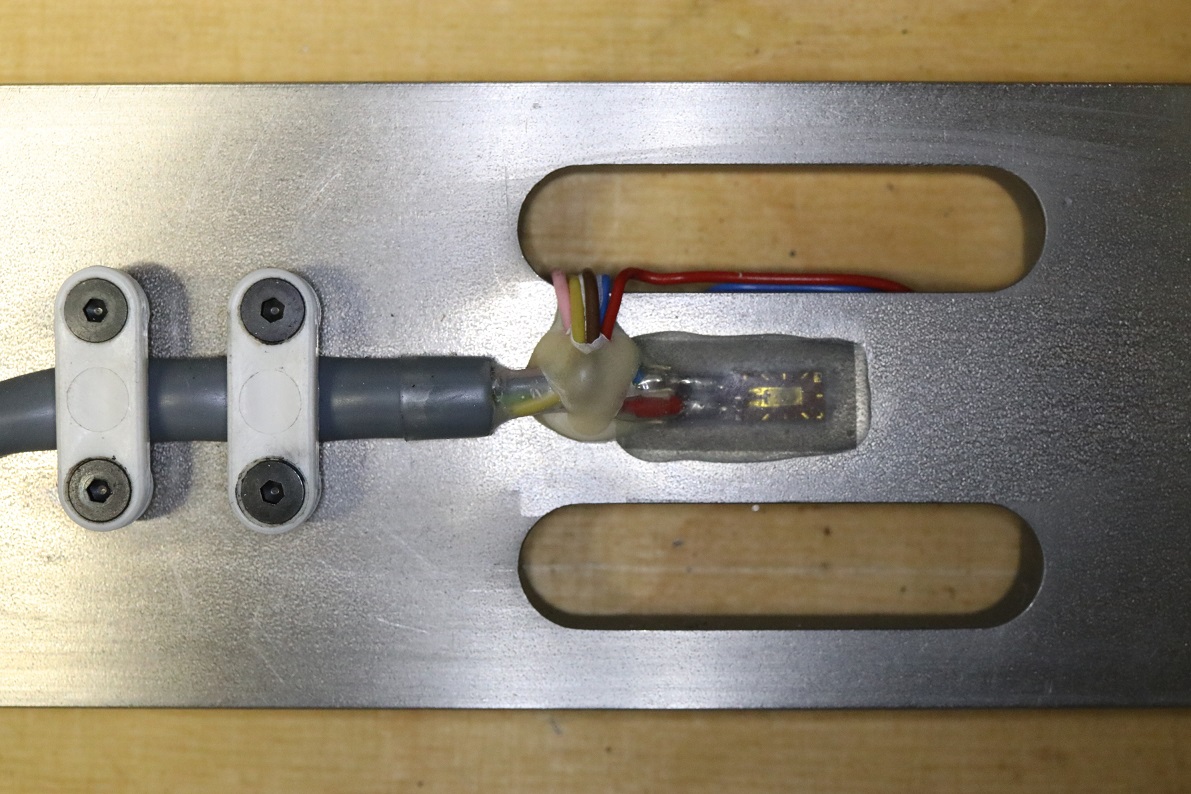

Figure: Optical strain measurement on an aluminium wire (left), and measurement with strain gauges (full bridge with bending and temperature compensation, right).