The analysis of mechanical and thermal loads as well as the experimental testing of materials and components require specialised know-how, software and elaborate test rigs. Our speciality is the acceleration of long-term damage mechanisms in the laboratory. Benefit from our expertise to optimise your systems and products!

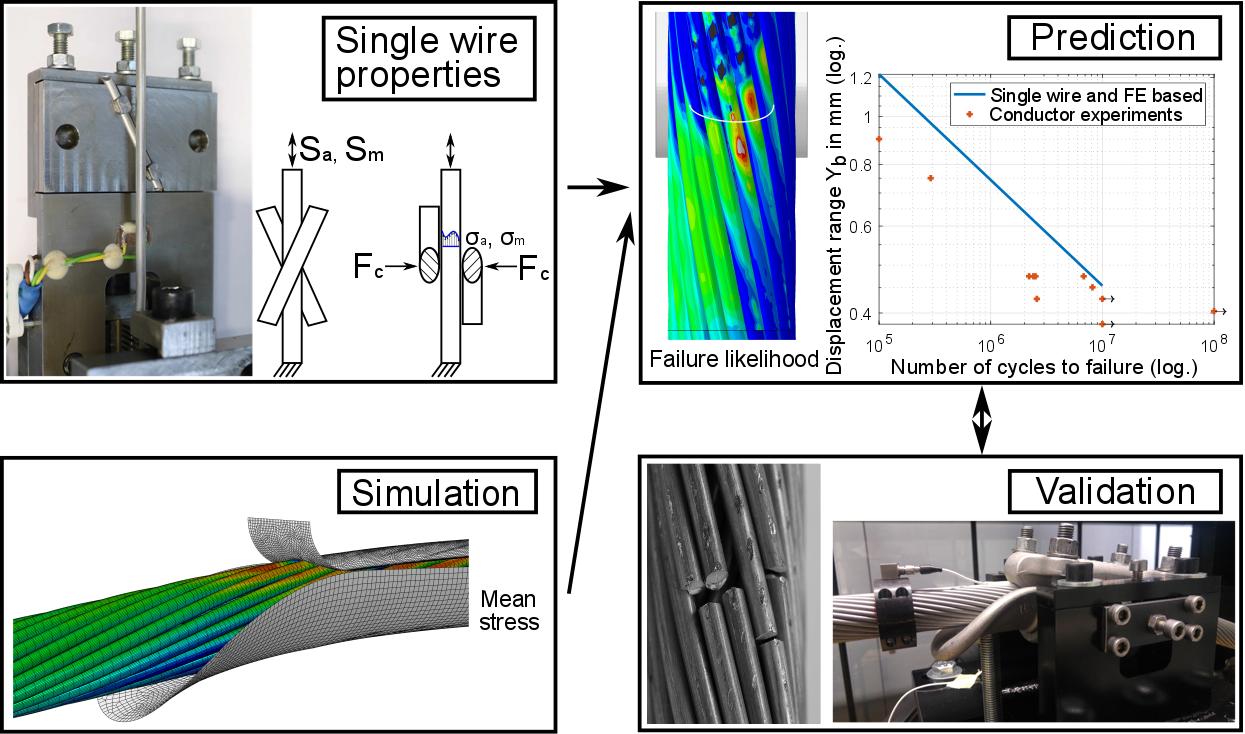

Figure: Characterisation of the fatigue behaviour (failure location and lifetime) by simulation and measurement.

Mechanical simulations are often limited by the underlying material models. Especially the typical conductor and fitting materials have a very low yield point, they often tend to creep even at room temperature and can lose strength in unfavourable operating conditions (e.g. due to recovery). We are specialised in the characterisation of such material properties and the modelling to make these data usable for the design.

Finite element simulations have become indispensable in mechanical and thermal design. The correct modelling of complex contact conditions and highly linear material behaviour in particular, however, remains a challenge. Yet simulations allow for a much more efficient design. Many of the relevant parameters cannot be tested experimentally or must be separated from other parameters and the influence of different test conditions. In design, there are usually too many parameters to investigate each one individually in elaborate component tests, and testing the long-term reliability with component tests is also very demanding.

Despite all the progress in design, the validation of simulation results with component tests is still indispensable. However, the experimental effort is much lower compared to the traditional test- and experience-based design, because the main focus is on the validation of the simulation results and the final design.

Such component tests are usually special set-ups, with high requirements for actuators, control systems, mechanics and metrology. However, they are essential in order to know the limits of the simulations.

Electrical contact resistance and fracture pattern cannot be reliably determined with simulations even today. However, the underlying mechanisms only occur during operation over the course of many years, so they must be accelerated in the laboratory for meaningful component tests. Some of the usual component tests, e.g. thermal cycles for type testing, are not very meaningful for the long-term behaviour of components. Component tests therefore also require material models in some cases in order to accurately represent the long-term behaviour.