Long-term damage mechanisms that in service often take place over many decades must be accelerated in the laboratory, both for component testing and for the determination of material properties. Grid infrastructure must function reliably over a much longer period of time than can be tested in the laboratory.

|

|

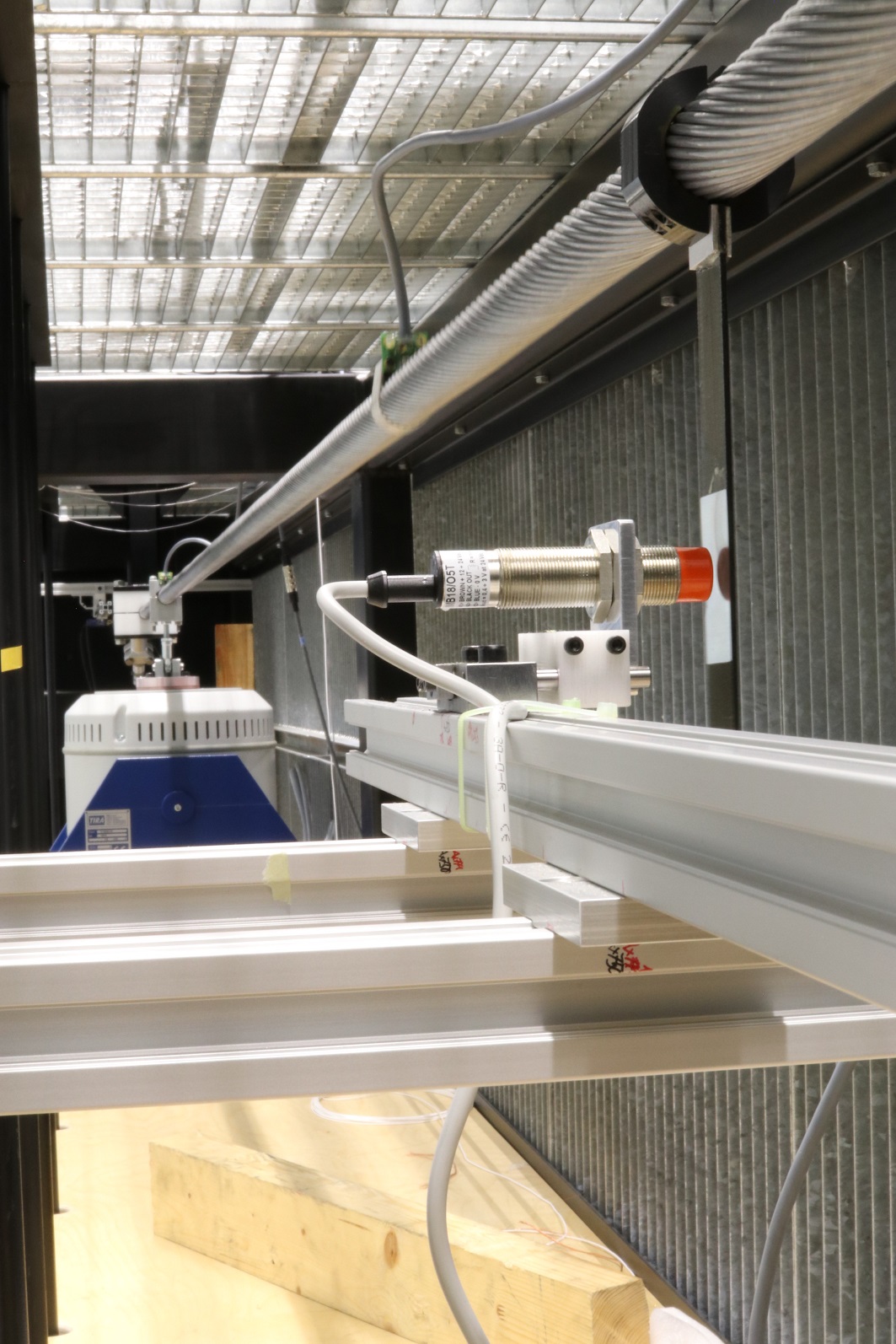

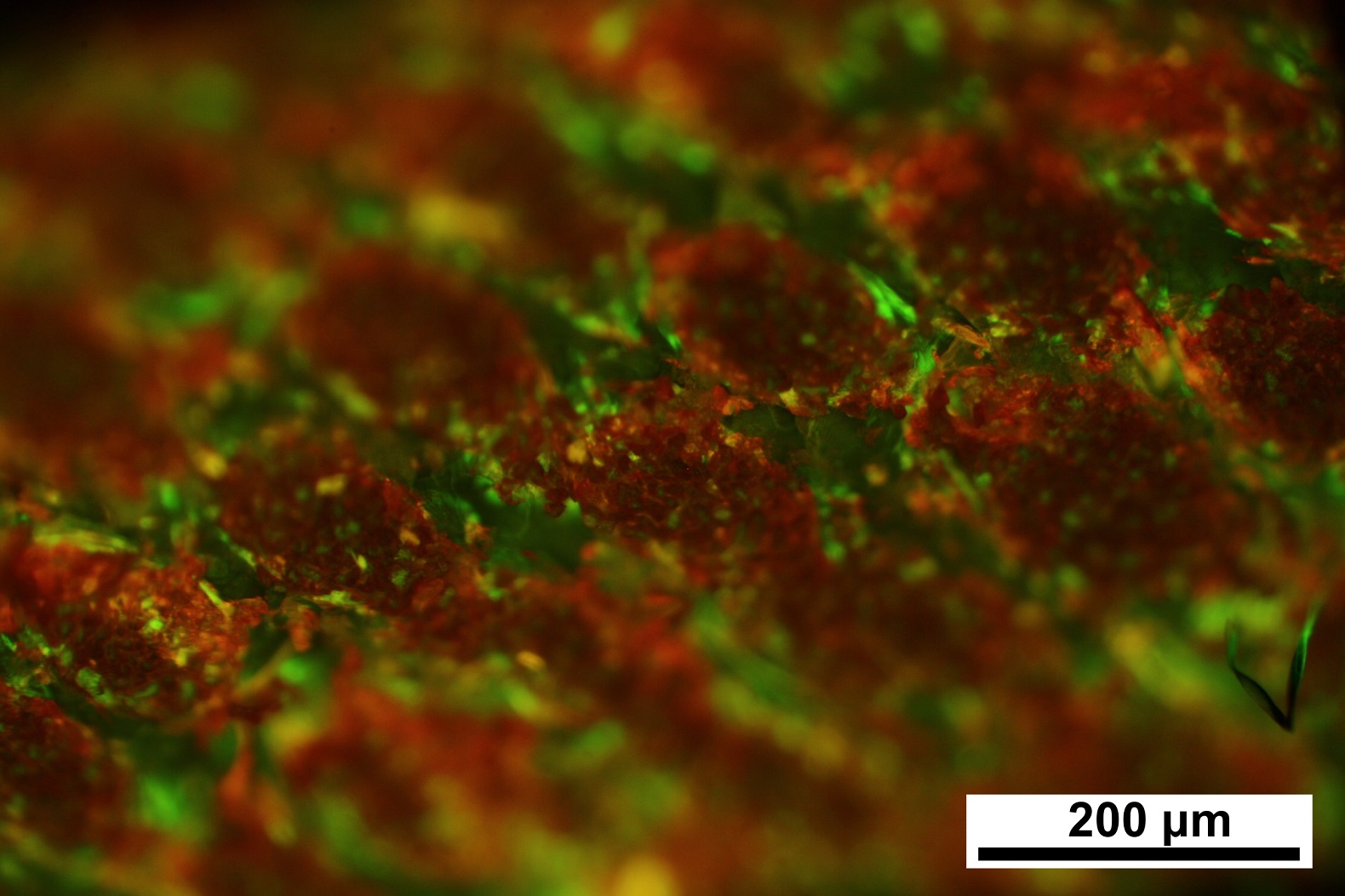

Figure: Fatigue test on an overhead line fitting (left) and investigation of oil penetration behaviour in hard fabric (cotton-phenolic resin) with fluorescence microscopy (right).

Models and experimental techniques to accelerate the damage are therefore often essential. For fatigue, for example, it is well established that there is a negligible frequency dependency for metallic materials at low frequencies. For the description of creep and softening behaviour, time-temperature parameters, and thus ultimately higher temperatures, are often used; for the swelling behaviour of plastics, higher humidities are used. The exact procedure therefore differs greatly depending on the damage mechanism.

This approach, known as accelerated life testing, allows the robustness and reliability of products to be tested more quickly and with relatively few components by increasing the load beyond normal operating conditions.

Metrology for determining the damage progress and checking the damage pattern are essential for the validity of the tests. Similar issues arise in asset management. Damages are often due to insufficient information about the condition and properties of aged assets. In order to prevent such failures, we are researching new measuring methods for the condition assessment in asset management. Due to the high investment sums, such measurement techniques have a great influence on the economic efficiency of assets.